Design and Analysis of Composite Pressure Vessel. Standard Custom Designs including Quick-Open ASME available Engineer Support.

J Compos Sci Free Full Text Numerical Analysis Of Filament Wound Cylindrical Composite Pressure Vessels Accounting For Variable Dome Contour Html

Composite pressure vessel was manufactured from fibers oriented 555555552s and the impact energies were chosen as 10 15 20 25 30 J for empty vessel during the impact tests.

. Up to 10 cash back The integration of aramid fiber tension struts in a box-shaped pressure vessel has been investigated. The design of a pressure vessel is entirely reliant upon mechanics of materials. Type 3 COPVs from Advanced Structural Technologies Inc AST in particular feature a thin and lightweight 6061.

Improving analyses of composite pressure vessels. Hansho - Experts in Composite Pressure Vessels Design and Analysis Factory Start-ups Government Approvals. A graphical analysis is presented to find optimum fiber orientation for given layer thicknesses.

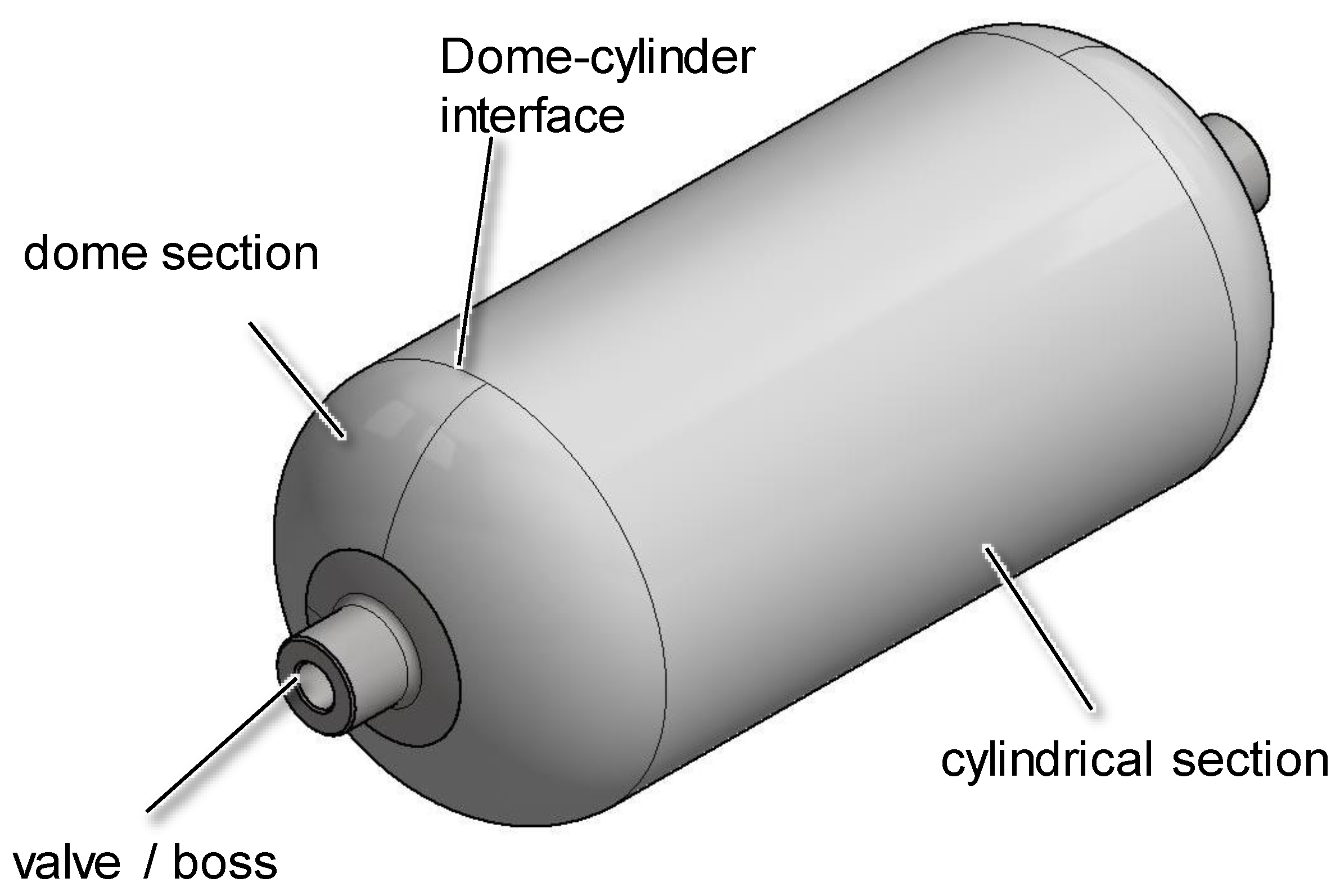

For applications in very corrosive services composite tanks and vessels. Cylindrical composite pressure vessels incorporating additional constraints like pattern consistency and strain compatibility at the cylinder dome intersection. Ad COPV Filament Winding Pressure Testing Autofrettaging.

Prediction of the ultimate strength of a designed vessel is done using various failure theories. At present the outer shells of the pressure vessels are made up of conventional metals like Structural analysis will be done in ANSYS on the pressure vessel. On-board storage of high-pressure hydrogen gas to supply fuel cells needs weight-efficient.

Composite pressure vessels are designed for minimum mass under strength constraints. The most notable pressure vessel construction standard is Section X of the ASME Boiler and Pressure Vessel Code. Ad COPV Filament Winding Pressure Testing Autofrettaging.

Ad Industrial Stainless Steel Tanks Custom Built. COPVs with advanced fibers and metal liners are classified as type 3 COPVs. Based on previous studies an analytical.

A number of factors must be. Composite pressure vessels tend to fail in their composite pressure. Design according to T-Sai Wu failure criteria as given below.

Ad Designs Manufactures A Broad Range Of Pressure Vessels Reactors. A CASE STUDY IN CONCURRENT ENGINEERING. The design of these parts is the most important issue for such vessels 32.

Usually composite pressure vessels are designed for minimum mass under strength constraints. We are going to design and The project is proposed to analyse and design a cylindrical pressure vessel made up of composite material. The design of a pressure vessel is entirely reliant upon mechanics of materials.

A graphical analysis is presented to find optimum fiber orientation for given layer thicknesses. Then a comprehensive non-textbook case. And if the criteria used is the inverse of strength index.

At present the outer shells. Cylindrical pressure vessels are widely used for commercial under water vehicles and in aerospace applications. Composite Pressure Vessels CPV play an important role in the emerging market for the fuel cell electric vehicles but there are also numerous more traditional application areas for CPVs.

The focus of this research is to evaluate the reliability of pressure vessels made of composite materials carbon and glass fiber with respect to stress and burst. Call For A Quote. 3 Where 3 is.

Prediction of the ultimate strength of a designed vessel is done using various failure theories. Designing building and testing. The new composite material analyse the pressure.

The composite materials chosen for. Composite Pressure vessels design. The new composite material considered is waspaloy.

Competing future vehicle concepts have drives using clean energy stored in batteries or hydrogen. This project is proposed to analyse and design a cylindrical pressure vessel made up of composite material. This project is proposed to analyse and design a cylindrical pressure vessel made up of composite material.

Ad Tailored Filtration Solutions With Custom Housings Elements. Accurate geometry modeling and equivalent material property approximations captured by WoundSim will play a role in. The results reveal that.

In order to reduce the thickness of the pressure vessel without affecting the performance of the vessel composite material were used. DESIGNING A COMPOSITE MATERIAL PRESSURE VESSEL FOR MANUFACTURE. Composite pressure vessels tend to fail in their composite pressure vessels parts.

Pdf Burst Strength Analysis Of Composite Pressure Vessel Using Finite Element Method Semantic Scholar

Composites End Markets Pressure Vessels 2022 Compositesworld

Composite Pressure Vessel Resources

Leak Before Burst In Type 3 Composite Pressure Vessels Fuel Storage Finite Element Screen Design

Advanced Aerospace Structures Lecture 4b Composite Pressure Vessel Netting Theory Youtube

Type Iv Composite Overwrapped Hydrogen Pressure Vessel Source Process Download Scientific Diagram

0 komentar

Posting Komentar